Products

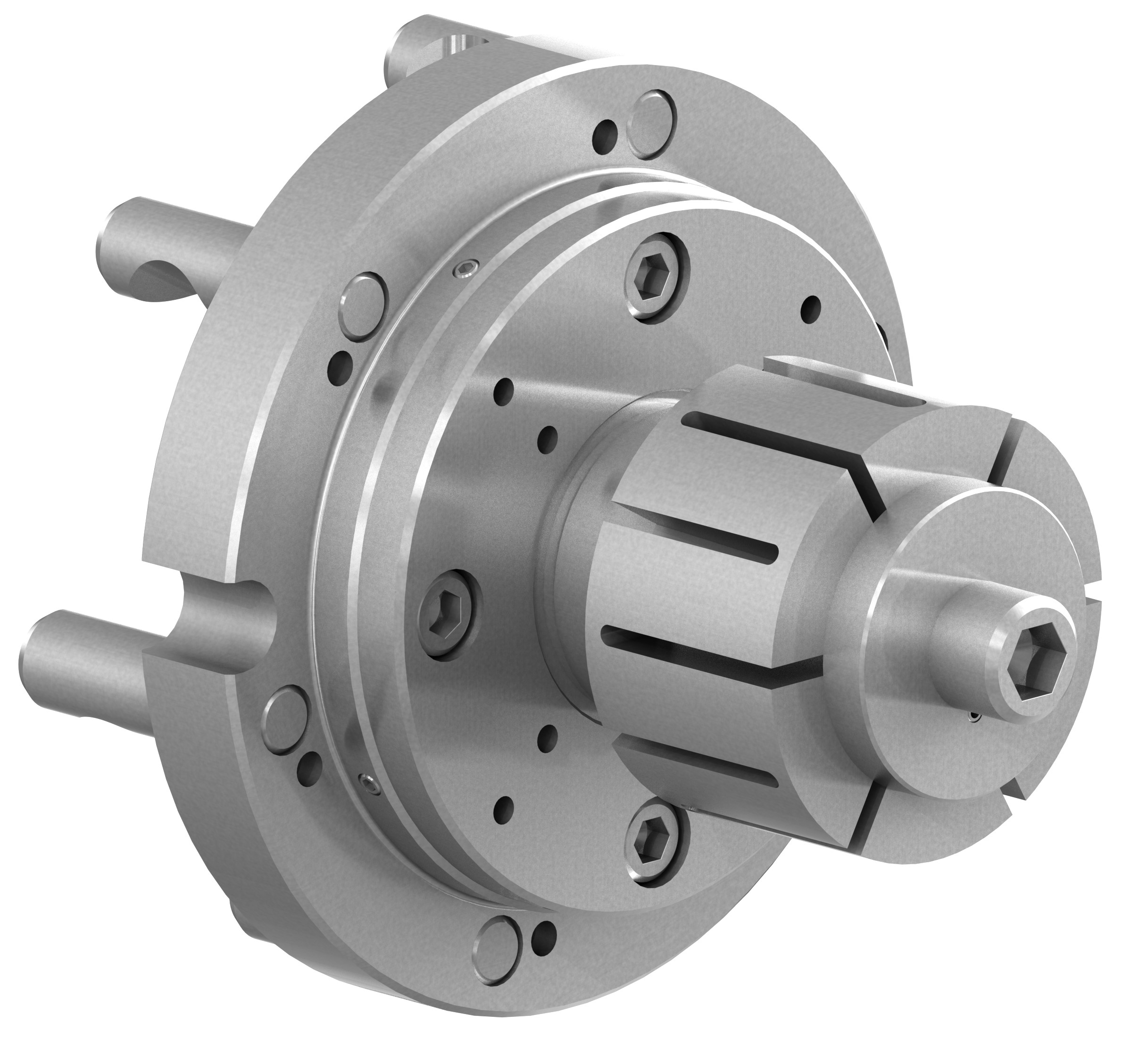

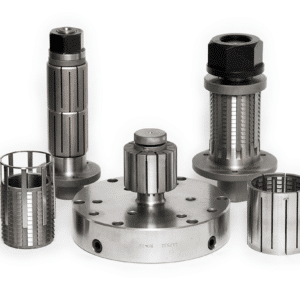

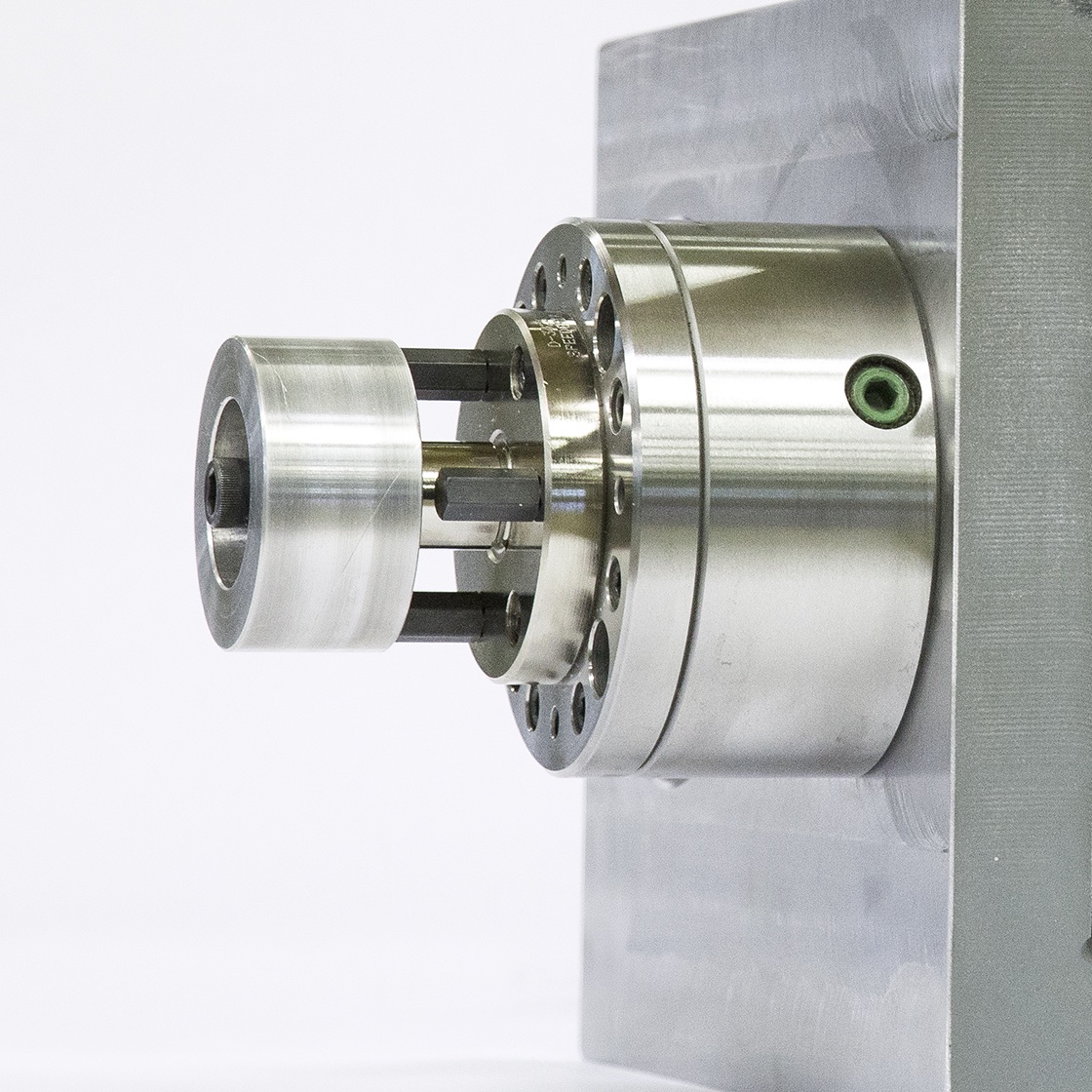

Speedgrip Chuck designs and manufactures internal and external gripping collet chucks, Cameron Sabertooth™ and internal and external gripping hydraulic chucks and arbors, diaphragm chucks, finger chucks, between centers mandrels, and Madison face drivers.

Our workholding equipment is very versatile and ideal for turning, drilling and milling operations, gear cutting and finishing, grinding, balancing, inspection equipment, and has many uses on fixtures plates and tombstones.

All Products Catalog

New Product Catalog

New Jaw Chuck Catalog

New Products

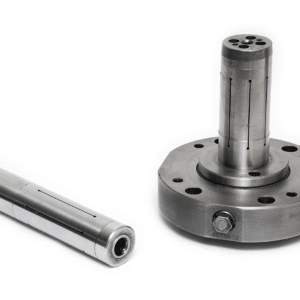

ID Mandrels

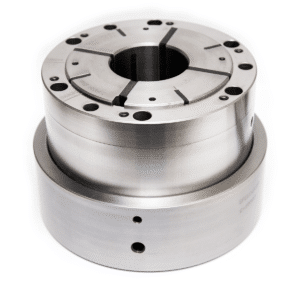

OD Collet Chucks

Quick Change

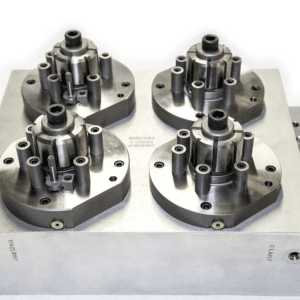

Engineered Workholding Solutions

Fixtures, Tombstones & Pallet Chucks

Cylinders & Actuators

Intelligent Workholding

Special Features & Coatings

Standard Products

Our vast line of in-stock, off the shelf standard workholding have made us well known in the market for our customers to tool up a machine to grip their parts quickly, economically, and yet with great precision.

With adapters for lathes, turning centers, gear machines, and grinders and actuators for machine centers, tombstones, and fixtures, we have what you need in-stock.

Custom Designed Products

Our engineering departments ability to design workholding for a specific part and operation that is practical, innovative, and cost efficient has given us the reputation for excellence of Engineered Solutions for your Precision Workholding.

Guideline of Chuck Options and Attributes

Speedgrip offers a wide variety of collets, chucks, and arbors. The following describes various types, their respective attributes, typical specifications, and uses.

Single taper: 2nd operation for bores with square face

- Uses: turning, drilling, milling, balancing, gear machining, grinding, inspection, and fixtures

- Least expensive

- Readily available Collets from ½” up thru 8” stocked in 1/8” increments and to 17” as non-stocked

- Strong pullback action

- Repeatability .0003-.0005 T.I.R typically

- Actuation available: manual, drawbar/tube, and built-in cylinders

Double taper: 2nd operation for bores with square face, multi-diameter

- Uses: turning, drilling, milling, balancing, gear machining, grinding, inspection, and fixtures

- Inexpensive

- Readily available Collets from ½” up thru 8” stocked in 1/8” increments and to 17” as non-stocked.

- Strong pullback action

- Repeatability .0003-.0005 T.I.R typically

- Actuation available: drawbar/tube, built-in cylinders, and manual in larger sizes

Reverse taper:

- Uses: turning, drilling, milling, balancing, gear machining, grinding, and fixtures

- “No” pullback action

- Inexpensive

- Readily available Collets from ½” up thru 8” stocked in 1/8” increments and to 17” as non-stocked.

- Repeatability .001 T.I.R typically

- Actuation available: drawbar/tube, built-in cylinders, and manual in larger sizes

Sabertooth: for long, thin and multi length parts

- Uses: turning, drilling, milling, balancing, gear machining, and fixtures

- Moderately cost effective

- Readily available Collets from 1/2” up thru 8 1/2” stocked in 1/8” increments

- With or without pullback action

- Repeatability .0006-.0008 T.I.R typically

- Actuation available: manual, drawbar/tube, and built-in cylinders

Standard External collet chuck

- Uses: primarily turning (some other operations)

- Robust (long grip length)

- Thru hole

- Quick change collets

- Readily available OD-3000 collet blanks in stock for ½” to 3” thru and 4 ½ diameter max

- OD-6500 collet blanks in stock for 1 ½” thru 6 ½” thru and to 8” diameter max

- Adapter options (A-2 5”, 6”, 8”, & 11”) are in stock (drawbar connector and workstops available)

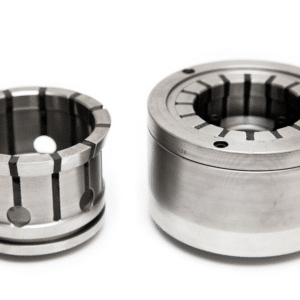

S.O.E. (Split from One End) Collet various operations of cylindrical parts

- Uses: turning, drilling, milling, balancing, gear machining, grinding, inspection, and fixtures

- Part specific / cost accordingly

- Greater expansion / clasp than other types

- Lower profile for tool clearance

- Available with or without pullback

- Actuation available: manual, drawbar/tube, and built-in cylinder as required.

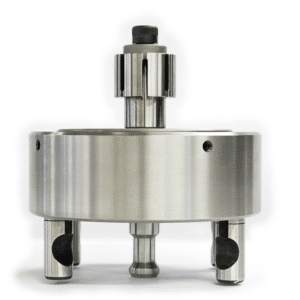

Diaphragm internal / external grip of 2nd various operations

- Uses: turning, drilling, milling, balancing, gear machining, grinding, inspection, and fixtures

- Part specific / cost accordingly

- Less part distortion

- Accuracy .0002-.005 T.I.R typical

- Excellent chip clearance

- Actuation available: manual, drawbar/tube, and built-in cylinder as required.

“Finger Collet” grip thin wall & distorted parts 1st op turning

- Uses: turning / lathes

- Part specific / cost accordingly

- Conforms to part shape

- Removes / reduces distortion improving for subsequent operations

- Actuation available: manual, drawbar/tube, and built-in cylinder as required.

Hydraulic chucks / arbors (Cameron Brand) higher accuracy parts various operations

- Uses: turning, drilling, milling, balancing, gear machining, grinding, inspection, and fixtures

- Part specific / cost accordingly

- Excellent repeatability .0002 T.I.R typical

- Excellent grip force

- Actuation available: manual, drawbar/tube, and built-in cylinder as required.

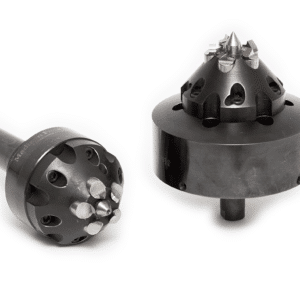

Facedrivers (Madison Brand) One operation machining of between centers parts

- Uses: turning, gear machining, and grinding

- Excellent repeatability (Hydra-Drive)

Face Drivers by Madison also carry a large inventory as follows:

- Morse Taper drivers

- Flange mount drivers

- Drives pins (various types sizes)

- Center points