SPECIAL FEATURES & COATINGS

Features

-

Chamfer & Steps - Collets can be chamfered or stepped to provide part and/or tool clearance.

-

Tapered - Collet OD or grip area can be tapered up to 7 degrees to match part and hold effectively.

-

Splined - Tooth configuration can be ground on the OD or in the ID for gripping the pitch diameter of the part.

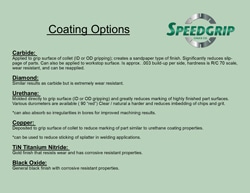

Coating Options

-

Carbide - Applied to grip surface of collet (ID or OD gripping); creates a sandpaper type of finish. Significantly reduces slip- page of parts. Can also be applied to workstop surface. Is approx. .003 build-up per side, hardness is R/C 70 scale, wear resistant, and can be reapplied.

-

Diamond - Similar results as carbide but is extremely wear resistant.

-

Urethane - Molded directly to grip surface (ID or OD gripping) and greatly reduces marking of highly finished part surfaces. Various durometers are available (90 "red") Clear / natural a harder and reduces imbedding of chips and grit.

*can also absorb so irregularities in bores for improved machining results. -

Copper - Deposited to grip surface of collet to reduce marking of part similar to urethane coating properties.

*can be used to reduce sticking of splatter in welding applications. -

TiN Titanium Nitride - Gold finish that resists wear and has corrosive resistant properties.

-

Black Oxide - General black finish with corrosive resistant properties.