Automotive Industry Application – Fast and Highly Accurate Part Inspection

The application:

An automotive component manufacturer needed to 100% inspect a critical feature on a high production volume turned part.

The challenge:

The production was very high, and the large daily quantities needing to be inspected demanded a rapid and reliable way to check the runout of an outside diameter groove to a turned bore.

The Speedgrip solution:

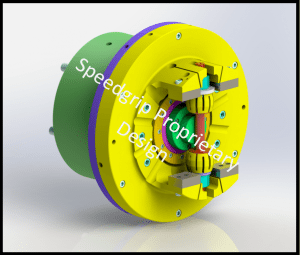

The mechanism for this application needed to be fast, robust, very accurate, and with high repeatability. One of our products stood out above the others: the Accu-flex arbor.

An Accu-flex arbor is manufactured to be slightly interfering with the part to be held. When the part to be held is loaded, a gentle force is required to move (either expand or contract) the segments of the arbor. With close customer part tolerances (.001-.002) accuracies of .0002 concentricity and repeatability can be attained. With larger customer part tolerances, we can guarantee .0005.

This deceptively simple mechanism is both highly accurate, and quite affordable in comparison to actuated workholding mechanisms. It can be mounted between bench centers on the shop floor. It has been successfully used for part loading on the end of robot arms, in fixturing applications to center a part before being clamped, on gear checker machines, in welding applications, in balancing and assembly operations.

The uses we are finding for Accu-flex arbors are continually growing. As much as they are already being used, I believe them still to be greatly underutilized. We are continuing to find and develop new and exciting uses for this product.

Let us help you improve your processes. Don’t be satisfied with things the way they’ve always been done. Our engineering team loves to help find solutions to your manufacturing challenges.

Dave Stokely

Chief Designer

Speedgrip Chuck, Co.

Automotive Industry Application – Fast and highly accurate part inspection

The application:

An automotive component manufacturer needed to 100% inspect a critical feature on a high production volume turned part.

The challenge:

The production was very high, and the large daily quantities needing to be inspected demanded a rapid and reliable way to check the runout of an outside diameter groove to a turned bore.

The Speedgrip solution:

The mechanism for this application needed to be fast, robust, very accurate, and with high repeatability. One of our products stood out above the others: the Accu-flex arbor.

An Accu-flex arbor is manufactured to be slightly interfering with the part to be held. When the part to be held is loaded, a gentle force is required to move (either expand or contract) the segments of the arbor. With close customer part tolerances (.001-.002) accuracies of .0002 concentricity and repeatability can be attained. With larger customer part tolerances, we can guarantee .0005.

This deceptively simple mechanism is both highly accurate, and quite affordable in comparison to actuated workholding mechanisms. It can be mounted between bench centers on the shop floor. It has been successfully used for part loading on the end of robot arms, in fixturing applications to center a part before being clamped, on gear checker machines, in welding applications, in balancing and assembly operations.

The uses we are finding for Accu-flex arbors are continually growing. As much as they are already being used, I believe them still to be greatly underutilized. We are continuing to find and develop new and exciting uses for this product.

Let us help you improve your processes. Don’t be satisfied with things the way they’ve always been done. Our engineering team loves to help find solutions to your manufacturing challenges.

Dave Stokely

Chief Designer

Speedgrip Chuck, Co.